Crawford’s Auto Repair offers air intake system repairs and maintenance. Of course this includes air filter replacement. Customers from Chandler, Gilbert, Sun Lakes and the surrounding area in the East Valley will find the shop conveniently located to make use of these services.

Schedule An AppointmentDoes your engine have stalling or poor performance? Are you due for an air filter replacement? Then bring your vehicle to Crawford's Auto Repair for affordable 5-star service. Call 480-201-0740 to schedule an appointment.

What Is The Air Intake System? Why Is It Important?

A lot of auto repair shops neglect to even mention the air intake system in their list of services. It’s not because they don’t offer it; it’s because the air intake system is so simple in comparison to other systems. There are relatively fewer parts to repair compared to other systems. The most common service, an air filter replacement, is often just an accessory to an oil change. Yet, no one can deny the importance of air intake in the process of internal combustion. Air intake is essential for the operation of your vehicle, and unlike other shops we wanted our website to be just as educational about auto mechanics as it is informative about our services.

Diagram showing the operation of a 4-stroke spark ignition engine. Labels: 1 ‐ Induction, 2 ‐ Compression, 3 ‐ Power, 4 ‐ Exhaust. CC-BY-SA 3.0 Zephyris

Internal combustion engines burn an air-fuel mixture to create power which drives the vehicle. The internal combustion occurs within cylinders that house pistons. Air and fuel are drawn into the cylinder. Then a spark ignites the air-fuel mixture which causes the piston to move down. There may be six or eight of these cylinders and pistons. They each fire in a specific order so that when one piston goes down, the adjacent piston goes up. As they go up and down, they systematically rotate a crankshaft. Then the rotational energy of the crankshaft is eventually transferred to the wheels through a series of gears and shafts. After the combustion, the burned byproduct exits the engine through the Exhaust System.

The Purpose Of The Air Intake System

The purpose of the air intake system is to allow clean air to enter the engine so that it can be mixed with the fuel and ignited. Technically, a basic air intake system is just a passageway. (There are more advanced systems as described below). Except in advanced systems, the engine does most of the job of drawing in the air since the pistons have a plunging-type effect. Engines of this type are also called “naturally aspirated” engines.

Parts Of The Air Intake System And Their Functions

An air intake system consists of an air filter compartment, air filter, mass air flow sensor, throttle body and intake manifold. The air filter blocks contaminants in the air from entering the engine. Without the filter, debris and dirt would get into the engine and damage it. The air filter also keeps contaminants off the air flow sensor.

The mass air flow sensor (MAF) monitors the mass flow rate of air entering a fuel-injected internal combustion engine. The air mass information is necessary for the engine control unit (ECU) to balance and deliver the correct fuel mass to the engine.

The throttle body controls the amount of air flowing into the engine in response to the accelerator pedal. The largest piece inside the throttle body is the throttle plate. The plate is a butterfly valve that regulates the airflow. When the accelerator is depressed, the throttle plate opens and allows air into the engine. At the same time the engine responds from the MAF and ECU signals to do more revolutions and draw more air in as the air becomes available. At the same time the ignition system and the fuel injection system are responding to provide the correct fuel and the spark. This is all done with the correct timing from cylinder to cylinder. The throttle plate closes as the accelerator is released. This effectively chokes off air flow into the combustion chamber, and the other systems also respond accordingly.

The main function of the intake manifold is to evenly distribute the incoming air to each intake port in the cylinder head. Its that last part of the air intake system before the air actually enters the engine.

The Carburetor Is An Outdated Method Of Air Intake

Prior to 1985 most vehicles used a carburetor. A carburetor is a primitive method of mixing air and fuel. It is far less efficient than modern fuel injection. Alas, it’s a main part of the air intake system (as well as the fuel system) that could have been discussed in detail since they required frequent tuning and rebuilding. Just like the cooling system has the radiator and the drivetrain has the transmission, this part was the hallmark of the air intake system (and fuel system). By the way, Crawford’s Auto Repair has the expertise to perform carburetor tuning, carburetor repairs and carburetor rebuilds if you happen to be driving one of those classics that still has one, but whether we could perform the service would depend on the availability of parts.

The absence of this part may be yet another reason why other auto repair shops don’t bother to mention air intake services. However, the history of the carburetor being replaced by fuel injection could very well be the same pattern that the air intake system follows as modern mechanics become more advanced. Fuel injection existed long before it became common. While the carburetor was being used in most vehicles for decades, fuel injection was reserved mostly for high performance vehicles and race cars. Yet, fuel injection became commonplace because it is more efficient. It produces better gas mileage and helps lower emissions.

Replacing The Carburetor Sets The Pattern For Other Future Advancements

If advanced air intake systems follow historic trends, then perhaps they will also become more commonplace. We mention some of these advanced systems below, partly because they are topics that racers would like and as mechanics we also love racing. But, who knows? Maybe in a decade there will be a turbocharger or a supercharger in every vehicle. Turbocharging is already pretty common, especially in diesel engines and luxury vehicles. If it results in lower fuel emissions and produces a higher-performing engine then that gives the gasoline vehicle an angle to compete against newly-developed hybrid and electric vehicles. Even hybrids could take advantage of the same technology.

Secondary Air Injection

Despite the name, secondary air injection is not part of the air intake system. It is part of the emissions system.

Cold Air Intake

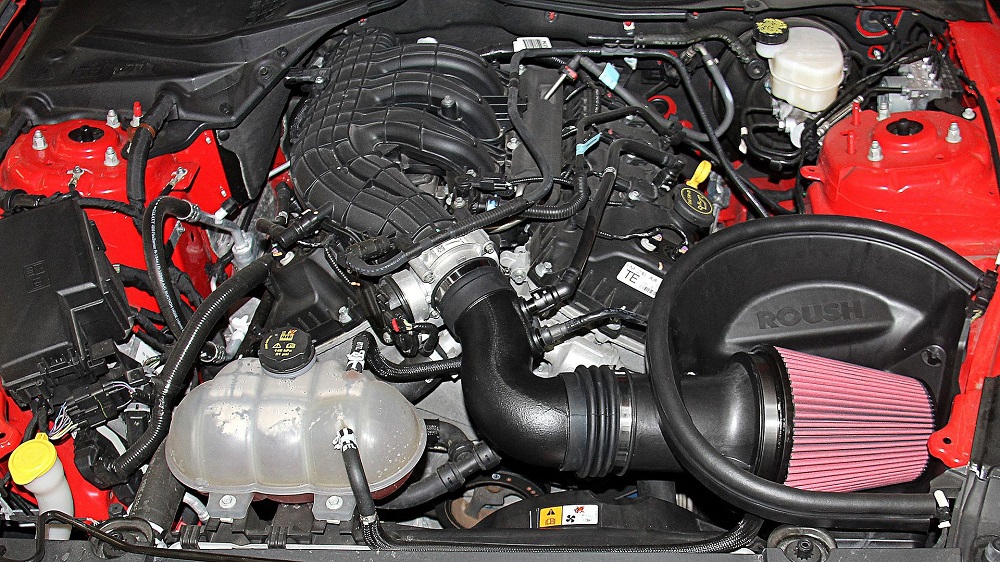

2015 Ford Mustang V6 Engine Bay with a Roush Cold Air Intake. CC-BY-SA 4.0 Karamitchen.

A cold air intake uses materials and design to allow more cold air to enter the engine instead of hot air. Theoretically this makes the engine more powerful, but another benefit may be that it makes the engine more fuel efficient.

Most vehicles manufactured between the mid-1970s and mid-1990s had thermostatic air intake systems. This controlled the air intake so that a hot engine would take in cold air and a cold engine would take in hot air. Thermostatic air intake systems have mostly been replaced by modern emissions systems and fuel injection. Now in modern vehicles, factory-installed air intakes are not temperature regulated. So the aftermarket provides cold air intake systems with the claim that cooler air has higher density. Since there is more oxygen per volume unit than warmer air, that means there is more air to burn which theoretically means more power.

Cold air intake systems often have a longer tube between the filter and throttle. Since the entry way for the air is held farther away from the engine, the heat of the engine doesn’t warm it as it enters the intake. Also the parts may be made out of more heat-resistant materials and the shape of the filter box shields some of the heat from the engine.

Cold Air Intake Installation

If you’d like us to install a cold air intake on your vehicle we’d be happy to. In most cases it doesn’t hurt the engine, although we make no claims as to whether it will improve the engine’s performance. There are parts for both regular gasoline and diesel. There seems to be a big market for these parts in diesel engines since diesel engines are more powerful, produce more heat, and require more emissions control.

Turbocharging

A turbocharger or turbo is a device that reuses exhaust from the engine and pumps it with turbines back into the engine. It forces more compressed air and proportionately more fuel into the combustion chamber than atmospheric pressure, which results in more power.

Turbochargers tend to be more efficient but less responsive than superchargers. The exhaust which drives the turbo is farther down in the internal combustion cycle than air intake, so a lag in timing has always been the main problem with turbocharging. However, modern advancements are always in development to reduce turbocharging lag to the point that the delay is not noticeable. For instance, a high quality, high performance vehicle like a Porsche might have a slight lag that is measurable but not noticeable.

Beyond Porches, turbochargers could be found in other cars, trucks and especially diesel engines and luxury vehicles.

DIY Maintenance Tip For Owners Of Turbocharged Vehicles:

If you have a turbo-charged engine, give the engine a minute or two to cool down before turning it off. This cool down period allows oil to circulate and cool down the bearings in the turbo. If you shut off the engine immediately after hard driving, the oil can gum up around the hot bearings and create problems down the road.

Supercharging

A supercharger also pumps compressed air into the engine giving it more power than natural aspiration.

While the exhaust drives a turbocharger, the engine itself drives a supercharger. A belt connects the the supercharger to the engine’s crankshaft– the very same crankshaft whose rotational energy is eventually transferred to the wheels to drive the vehicle itself.

There are pros and cons to this. A pro is that the engine crankshaft generally provides a better drive than the exhaust, and ensures that there is no lag. (The same principle is applied with the drive belt to ensure that the camshaft rotates in sync with the crankshaft which ensures that the intake valves open in harmony with the pumping of the pistons). Because of this a supercharger can work at low RPM, while a turbo only works at higher RPM. The con to having a supercharger directly connected to the crankshaft is that it puts more mechanical stress on the engine.

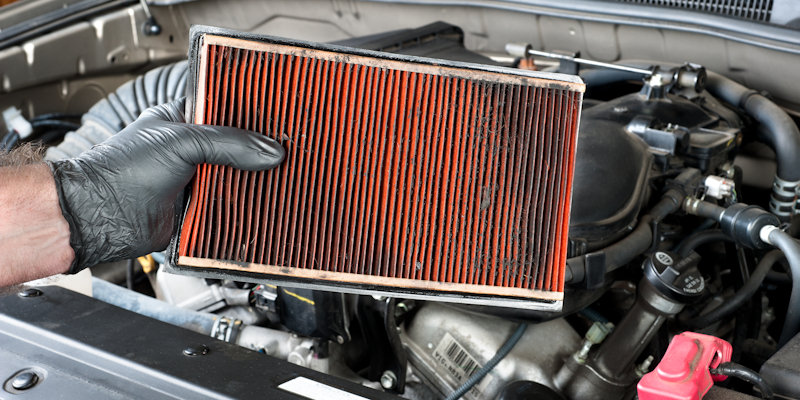

Air Intake System Maintenance – Air Filter Replacement

The most common air intake system maintenance service is an air filter replacement. We replace the air filter every third or fourth oil change (about every 15,000 to 20,000 miles). Regularly driving on dirt roads would require more frequent replacement. The air filter is relatively inexpensive and replacing it does so much to protect the engine.

Other maintenance services could include disassembling the air intake system from the filter case to the intake manifold and cleaning it. This includes cleaning the mass air flow sensor.

One service that we do NOT recommend as standard maintenance is an air induction cleaning without disassembly. This involves spraying a solvent into the intake manifold through the throttle body. This solvent breaks down the dirt and oil residue that has accumulated on the inside of the intake manifold and cylinder heads. The dirt then enters the cylinders of the engine and can cause damage. To properly clean an air induction system, the parts should be removed before they are cleaned so that the contaminants don’t get into the engine. In most vehicles you never need to perform an air induction cleaning. For some diesel engines it may be necessary on occasion. See 3 “Standard” Maintenance Services That Are Complete Nonsense.

Air Intake System Warning Lights

The following warning lights are directly related to the air intake system and indicate that the vehicle needs service.

Check Engine Light

Your vehicle will not pass an emissions test when this light is illuminated. It could indicate anything related to the engine, the ignition system or the exhaust system. Learn more about the Free Check engine Light Diagnostic.

Air Filter Clogged Indicator

This light means you need an air filter replacement. We check the air filter with standard maintenance and oil changes, but if your vehicle has this light then the replacement needs to be done sooner.

Temperature Light (Hot Engine Temperature Light)

This is an extreme case, but if air isn’t allowed to get to the engine then it can overheat. Also watch the temperature gauge and other temperature lights (oil temp, etc.)

If this light is blue don’t worry about it. But if it’s red, orange or yellow it indicates that the engine is running hotter than normal limits. This light means pull over now as safely and as soon as possible. After you manage to pull over have the vehicle towed to the shop. Most of the time this light is due to cooling system failure. The technician’s job is to diagnose whether the problem is related to the air intake.

Low Coolant Level Light

The low coolant light could come on with or without the hot temperature light above. You can keep driving if the hot temperature light above is not illuminated, but keep a close eye on it and have the vehicle serviced as soon as possible. If the temperature light comes on you should pull over. The reason this light can come on is because the engine will have a higher coolant demand if it is overheating from lack of air.

Charging System Light

Oddly this light can come on too. If the engine isn’t producing enough power due to lack of air then it isn’t recharging the battery.

There are other general warning lights, see the Dashboard Warning Light guide.

Signs Of A Failing Air Intake System

- Reduction in engine performance.

- Engine overheating.

- Additional coolant requirement, and water pump failure.

- Engine stalling.

- Noises from the engine.

- Low speed attainment (unable to obtain high speeds).

- Sputtering at high speeds.

- Higher fuel consumption.

- Black smoke.

- Problems with battery charging.

- Engine won’t start or starts with difficulty.

- Poor AC performance.

A lot of these can be signs for other faulty systems or parts. It will be the technician’s job during the inspection to determine the source of the problem.

Air Intake System Repairs

For basic air intake systems the repair involves clearing the airway. The first step is an air filter replacement. If that isn’t sufficient then we do an air intake cleaning job. This involves disassembling the system and it includes throttle body cleaning. Occasionally warning lights and symptoms from other systems will lead to the discovery of a dirty or faulty mass air flow sensor which would require MAF sensor replacement or MAF sensor cleaning.

Here is a more complete list of air intake system services and repairs:

- Carburetor tuning.

- Carburetor repair.

- Carburetor replacement.

- Carburetor rebuild.

- Camshaft position sensor replacement.

- Top dead center (TDC) sensor replacement.

- Air injection hose replacement.

- Air charge temperature sensor replacement.

- Air cleaner temperature sensor replacement.

- Mass air flow sensor cleaning (MAF sensor cleaning).

- Mass air flow sensor replacement (MAF sensor replacment).

- Throttle position sensor replacement.

- Throttle body replacement.

- Throttle cable replacement.

- Throttle cable repair.

- Throttle controller replacement.

- Throttle-accelerator pedal position sensor replacement.

- Intake manifold gasket replacement.

- Intake manifold runner control replacement.

- Manifold absolute pressure sensor replacement (MAP sensor replacement).

- Manifold temperature sensor replacement.

- Air filter case replacement.

Schedule An Appointment For Air Intake Services At Crawford’s Auto Repair, Call 480-201-0740 Today

Is your vehicle is choking, sputtering or not starting? Are you due for an air filter replacement? Bring your vehicle to Crawford’s Auto Repair. Our experienced technicians can determine whether the source of the symptoms usually within an hour. We’ll treat your vehicle as if it belonged our own mother and we never try to sell unnecessary repairs. Call 480-201-0740 to schedule an appointment today.

No Comments

Sorry, the comment form is closed at this time.